Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Y3140CNC7

Brand: TOMAN

Place Of Origin: China

Whether CNC Machine Tool: Cnc

Status: New

Types Of: Gear Hobbing Machine

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Engine, Gearbox, Motor, Gear, Pump

Warranty Period: 1 Year

Core Selling Point: Automatic

Applicable Industry: Energy &Amp; Mining, Manufacturing Plant, Farms

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): India, Malaysia

Packaging: Iron

Productivity: 10000

Transportation: Ocean

Place of Origin: China

Supply Ability: 1000

Certificate: CE/ISO

HS Code: 8461401900

Port: Ningbo Port,Shanghai Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA

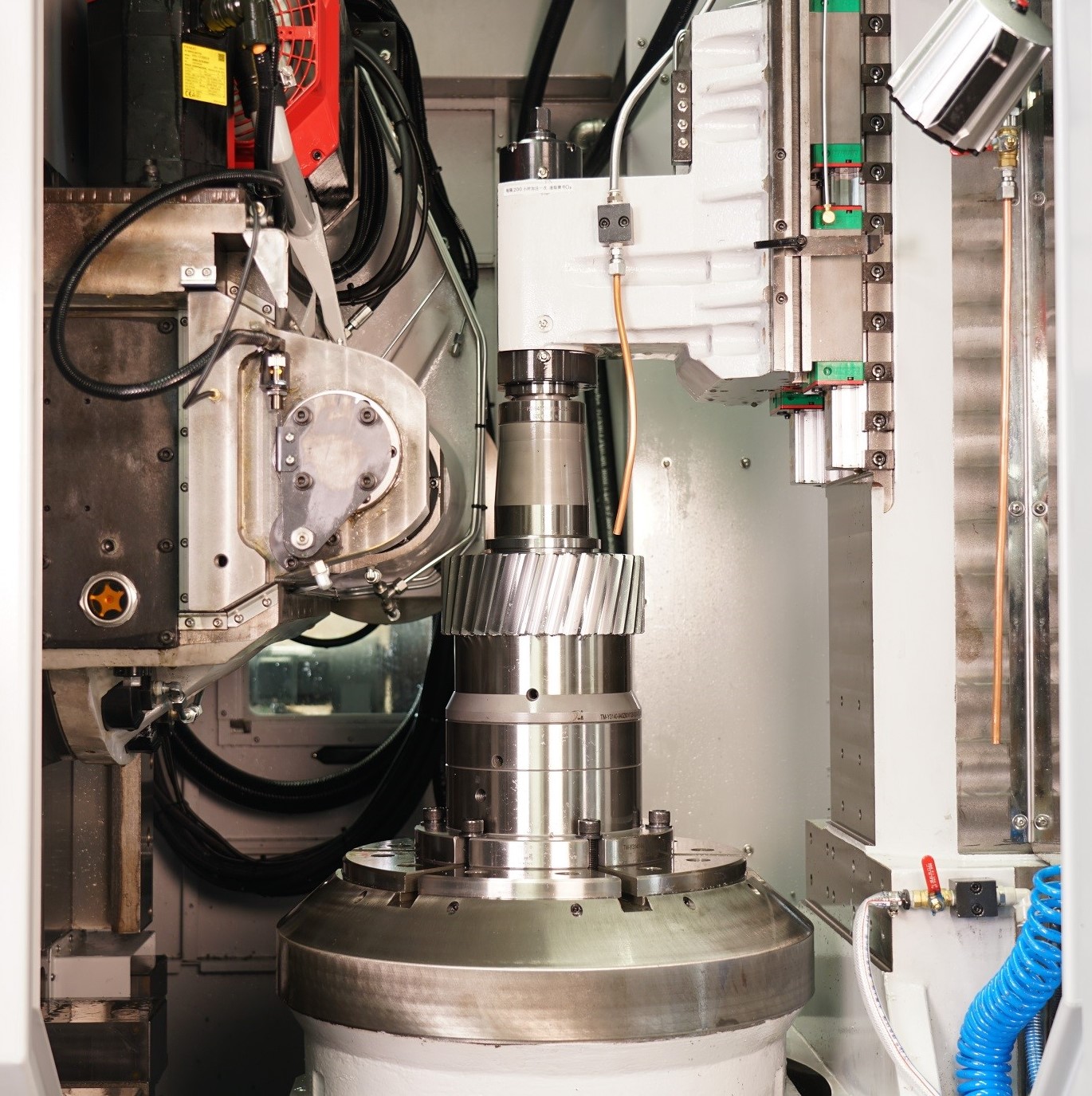

Y3140 CNC7

a versatile Hobbing Machine suited for large sized gears

A powerful 7 axis full Cnc Hobbing machine

An extremely rigid hobbing machine

FANUC numerical control system and servo drive, system reliability, simple operation

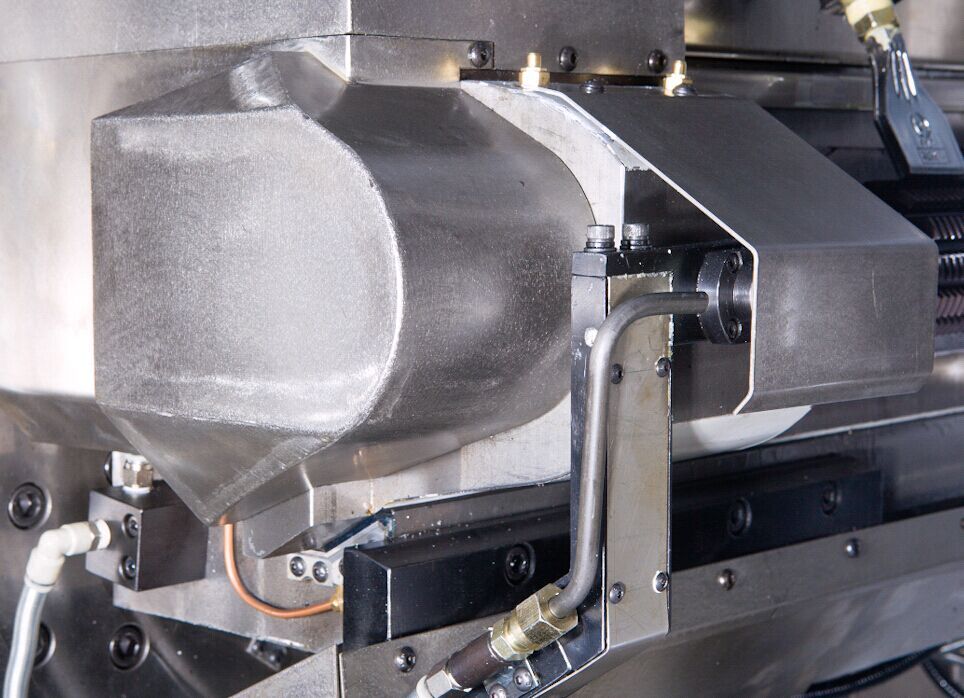

Wet Cutting Hobbing Machine

| Max. Workpiece Diameter: Φ400 mm |

| Max. Module: 12/16 |

High precision machining gear of construction machines :

(A substantial, accurate and extremely rigid hobbing machine)

1) CNC hobbing machine processing range is larger, the maximum processing diameter φ400mm.

2) Full CNC hobbing machine with 7 axis 4 linkage.

3) The workpiece shaft (C axis) adopts imported high precision, large number of gear transmission, higher precision, longer life, easy to adjustment, high speed, and very suitable for large module and less number of gear processing.

4) Hob spindle (B axis) adopts double row short cylindrical bearing and thrust bearing in front end + double row short cylindrical bearing rear end structure, the rigidity will be much better.

Use large inertia flywheel clearance structure in the end, it will be more stable and reliable, more suitable for heavy cutting. Precise progressive quantitative thin oil lubrication system is adopted to effectively control the temperature rise of the transmission gears.

5) The axial feed (Z axis) adopts servo motor direct drive, higher precision of feed interpolation.

Meanwhile, the center of the screw is colocated with the center of the middle guide, resulting in high guiding accuracy and better rigidity.

7) The cutting oil circulates in the inside of the bed, which effectively controls the temperature difference of the machine tool and ensures the thermal balance of the whole machine, which ensure the accuracy of the product

and the consistency of processing.

Main Technology Parameter

| CNC hobbing machine | Unit | TMY3140 |

|

|

| Wet hobbing |

| Maximum workpiece diameter | mm | Φ400 |

| Maximum module | mm | 12 |

| Worktable surface diameter | mm | Φ320 |

| Hob maximum assemble diameterx length | mm | Φ240x300 |

| Horizontal distance between hob center and worktable center | mm | 50-345 |

| Maximum hob axial movement amount | mm | 200 |

| Hob head slide travel (Z axis displacement) | mm | 200-600 |

| Max. swiveling angle of the hob head | Deg | ±45° |

| Hob spindle motor power | KW | 15 |

| Maximum hob spindle rotate speed(B axis) | rpm | 500/750 |

| Maximum worktable rotate speed(C axis) | rpm | 75 |

| Radial feed speed(X axis)(stepless) | mm/min | 1-2000 |

| Radial maximum rapid moving speed(X axis) | mm/min | 5000 |

| Axial feed speed(Z axis)(stepless) | mm/min | 1-2000 |

| Axial maximum rapid moving speed(Z axis) | mm/min | 6000 |

| Tangential travel feed speed(Y axis)(stepless) | mm/min | 1-1000 |

| Tangential maximum rapid travel speed(Y axis) | mm/min | 2500 |

Standard Configuration

| Hob arbor assembly ( Φ40) | hydraulic system |

| Hob arbor automatic clamping device | NC controller system |

| Workpiece automatic clamping device | NC data memory card |

| Spindle positioning | Operational software |

| Fully-enclosed safeguards | Residual-current circuit breaker |

| Woking light | Hands action button |

| Three colour lights indicate machine status | RS232C connector |

| Workpieces counter | Air conditioner for electric cabinet |

| Main spindle ampere meter | Chip conveyor |

| Chip cart | Automatic lubrication system |

| Cutting oil tank | Mist collector |

| Cold spray gun | The sizing block for machine adjustment |

Optional Configuration

| Automatic loading/unloading material device | Workpiece clamping |

| Automatic material storage | Workpiece rough locator device |

| Deburring device | Automatic tooth align device |

| Independent hob adjustment device | Oil cooling device |

| Hob arbor assembly:(metric system:Φ22, Φ27, Φ32, Φ50, Φ60),(Inch system: Φ26.988, Φ31.75, Φ38.1, Φ50.8) | |

Application

Construction Machine Gear

Marine Gear

Large Reduction Gear

Wind Power Generator Gear

WHY CHOOSE US?

2. Certification--CE/ISO, First prize of science and technology award, National key high tech enterprise and so on.

3. Quality Control--Quality checks to promise stable quality and high reliability for you.

4. Best Material--Insist on choosing top materials.

Product Categories : CNC Hobbing Machine Application > Construction Machines Gear Hobbing Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.